Only negative I’ve noticed so far with the SV06 ACE’s print quality is that overhangs tend to curl up. I know a little curling is unavoidable (depending on the overhang angle), but the curl I’m seeing seems excessive, leads to messy-looking undersides of overhangs, and can even cause prints to be knocked off the bed (when printing parts with small bed contact area and no brim).

Any and all tips are welcome; in the meantime, I’ll write up what I can think of that might be relevant in case other folks are having similar issues.

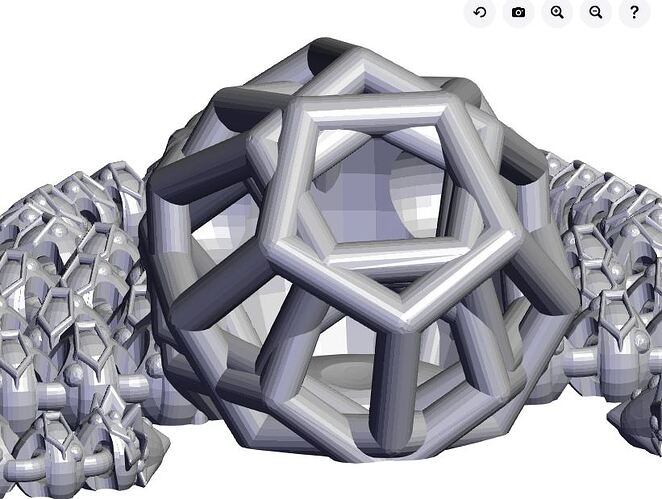

Here’s an example of a print where I hit the issue (STL from here, though it’s a paid model, sorry). The print finished successfully, but with visible curling as it printed (that eventually got “squished flat” as the opposing overhangs merged together). Some problematic areas are circled:

I also tried printing this overhang test, but the print consistently fails in the 55–60 degree range. The curling gets excessive, the nozzle starts hitting the print, and the print eventually detaches. (I can retry in a bit with a brim to see how the print quality turns out when I take bed adhesion out of the equation.)

I read through this thread about a similar issue on the base SV06 model, but the solution recommended there doesn’t seem applicable to the ACE, which has an entirely different fan shroud. (FWIW, I did make sure the fan shroud is fully tightened, and angled as close to the nozzle as possible.)

I’m using PLA that’s been dried thoroughly and otherwise prints well. I haven’t changed any cooling or speed settings from the latest profile in OrcaSlicer Git, but for reference, slicer settings are as follows:

I also tried cranking the fan up a bit to a constant 90% + 100% on overhangs, but other than making the fan noticeably louder (it’s really whiny above about 80% / 10,000 RPM), there was no difference in printing.

I wonder if I’m just printing the walls too fast for the filament to adequately cool? I can retry the overhang test with lower wall speed and see how that goes.