please take a look at this thread, maybe it could help:

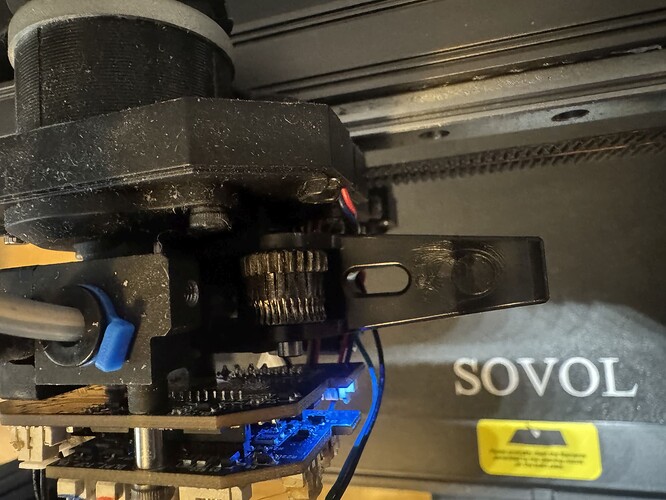

The picture shows just an extruder gear (for me):

Mine:

wrusman:

and I don’t see the different (or do I have the same problem)?

maybe it could be the problem. before i printed the solution my metal shaft was not visible so much like yours. the official wiki shows a bit more:

Unable to extrude the filament | Sovol 3D Printer Wiki

(4)Check the metal shaft of the extruder wrench. If the metal shaft moves, it will cause the position of the extruder gear to be misaligned. Please push the metal shaft back to its original position and fix it. If there are residual debris on the extruder gear, please use tweezers and a brush to clean it.

The shaft should not be visible at all, if sticks out as much as yours the extruder will most probably not work well.

the shaft…omg! Now I see what you mean! Also, this video helped me A LOT:

Now I fixed it:

Before:

Solved:

You are my hero!

Test the wires and the plugs, inside the printer extruder head. May be try unplugging and plugging it back it both the hotend and the thermostat

It will work lose again unless you use the fix above

Erf, i ignored this possibility because you said that you checked all part ![]() but that that is very difficult to identify. This print is a must have for the SV08 SV08 Extruder fix by Valerie Moore | Download free STL model | Printables.com (i using the one in one part with no gap, that is perfect).

but that that is very difficult to identify. This print is a must have for the SV08 SV08 Extruder fix by Valerie Moore | Download free STL model | Printables.com (i using the one in one part with no gap, that is perfect).

With the hardened nozzle, I have many clogged nozzles with PETG (jayo, sunlu, eSUN). I tested 4 nozzles, allways with a new SV08 Extruder Replacement Kit…

All orca calibation steps looks ok (and no clogging), just the “Orca Tolerance Test” went wrong and with clogging.

With Hardened Steel nozzles you have to increase the hotend temp by 5*-10*.

Increasing nozzle temperature with steel nozzles is usually all it takes to compensate for lower heat conductivity.