Hi everyone, I just got a Sovol zero for my birthday this year and I have been having basically nothing but issues with it, I’m having almost constant layer shifts and adhesion issues. I have not changed any of the settings other than doing my own input shaping and pressure advance. This is not my first printer either I have had I believe 4 or five others before this and I am lost on what to do because they do not seem to have any support on it.

When my Zero arrived there were a lot of loose nuts and screws. Make sure the print head and hotend are not loose and also check the x,y belt tensioners are not loose and that your belts have the correct tension.

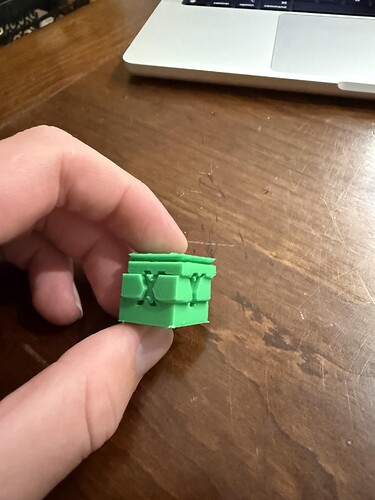

An X & Y shift in a cube…since the bed doesn’t move, the nozzle has to be hitting it.

My first thought, would be to thoroughly clean the plate to rule out any adhesion issue.

But, since you have both X & Y shift, I assume it stuck to the plate.

You’ve had other printers so should know to stay away from Grid like infill patterns.

I also assume you’ve run the calibration test during setup & maybe a few time since..??

I would pull off the hotend cover to make sure that the nozzle & setup are tight & don’t wiggle.

Also check the toolhead mounting plate.

After looking for anything obviously loose or out of adjustment, I’d try repeating the print and watching it super closely to see if I can see or hear what is happening. Taking an up close high quality video that you can play back in slow motion or frame by frame might also be helpful.

My guess is belt slip or a stepper losing steps. Adjusting printing speeds and accelerations might help reveal the trigger.

Lower your bed and use a finger to press up on the (cold) nozzle. Tighten anything that wiggles. If nothing wiggles home your printer and set for a long SLOW Z axis move. Watch for biding or jerky movement as the bed lowers.

I just witnessed a layer shift like this in real-time. Having a travel move be diagonal with full 1200 travel speed at 40k accel did cause a skip.

A diagonal move is only using a single stepper motor so that puts the maximum amount of torque into a single pulley making it so much more likely to skip either at the start or end of the travel move.

So either find a way to reduce diagonal travel moves if belt tension is correct. Turn down travel acceleration. Tune tension.

It’s odd that you seem to be having layer shifts in X and Y. Often it’s one axis or the other. The Zero is a high speed printer capable of 4 G acceleration. It does not have weak motors on the edge of skipping steps. In addition to the good mechanical suggestions already provided (which I’d do first), I’d then test the power supply voltage under load and try to verify the stepper motor controllers are configured for the proper current. If the current is low on the stepper motors, that could cause both stepper motors to lose steps.

One other mechanical suggestion before digging into possible stepper motor current issues: I’d disable the stepper motors and move the tool head on the X and Y axes by hand, across the entire range. It should move easily in all directions. If not, clean and lubricate the linear rails.

i have one Aswell i had a similar issue it was just belt tensioning and vibration comp