the Sv08 is 700mm/s and the SV Zero is 1200mm/s . What makes the zero so much faster?

@sovol3d

Maybe a reply?

The Zero is tiny. Gantry is smaller and lighter. Also the shorter span is more rigid.

Lighter and more rigid = higher acceleration

Thanks for reply. Looks like 48Volts to steppers too.

The stepper drivers for the Zero are capable of 48V for even greater acceleration (4g isn’t good enough?!?) but the Zero uses 24V in its stock configuration. I’d seen that 8.5 g acceleration video and it’s scary! ![]()

It’s advertised as 1200mm/s velocity. Are you saying that it doesn’t do that out of the box?

The video above is someone modding from 24v to 48v.

It will no make very good prints, it’s just showing that it can be done.

Is the 1200mm/s spec that sovol advertises assuming the 48v mod or is that spec for the 24v ?

1200 mm/s is the spec for the Zero, using 24 volts to power the stepper motors. That’s an extreme case travel speed and not the printing speed, and even then it’ll take some time to ramp the speed up to 1200 mm/s, although with 4 g acceleration it won’t take too long. The Zero should be able to produce good quality prints as fast as the filament will melt, and the Zero has a higher power nozzle heater and longer melt zone to melt plastic as fast as possible. There is always some specsmanship in 3D printer marketing but Sovol seems to be more truthful in their marketing than most. The Zero is indeed a very fast little printer. It’s not quite as fast as a delta printer that’s three times the price, but it doesn’t have the issues of delta printers and all of these high speed printers are mostly limited by how quickly plastic can melt. Crank up the speed and the cooling and the layer strength suffers.

Based on the design and the specs, Sovol packed a lot of capability into the Zero and did a good job of optimizing all of the design elements against each other to avoid any one aspect of the design limiting the overall design.

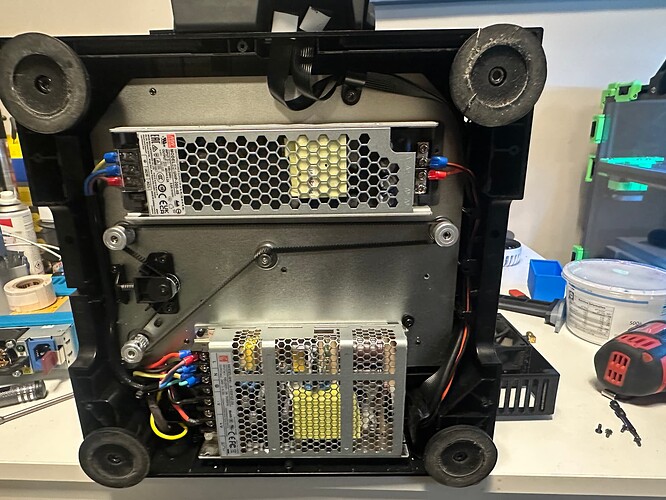

Did anyone manage to replicate putting a 48V psu in? I’ve got a MeanWell LRS-150 48V that I was thinking of trying to use.

Putting more power into the motors will make it possible to move the motors faster…

It, however, does nothing to change the resonance frequency of the entire printer. An unmodified SV08 is (probably) already capable of moving faster than it can produce a satisfactory print.

You’d think so - but the current speedboat benchy record is held by a PLA 3D printed printer (T250), which utilises the lack of rigidity to achieve accels of 250k and velocity of 4000mm/s. And it’s bigger than the Zero so size isn’t the determining factor either.

Rigidity is only important if your printer is designed to be rigid.

No. For an “open loop” position system rigidity is important if you care about the shape of your prints.

Does the record holder have a 6 axis IMU on the toolhead? If you measure the position of the printhead at the print head you can account for flex.

Your printer, however, only knows where it has commanded the motors to be.

And if the table on which the printer is placed is also rigid.

Or, you measure vibrations and mathematically compensate - its called Input Shaping.

Take a look - you can see the quality too. https://youtu.be/qVF_iwO3d04?si=w1B78RvhiXAkX8-2&t=696

Input shaping (as implemented by Klipper) changes the motion input speeds/acceleration to PREVENT the decoupling of motor position vs nozzle location.

It DOES NOT predict the deflection and adjust the motor angles to compensate for deflection in the motion system.

Did you watch the video you linked? The entire T250 printer is TUNED to be critically dampened knowing the mass of the (very impressive) toolhead and gantry.

The SV08 has as much in common with a T250 as a Camry has in common with a Veyron. A bigger motor (48V power supply) will simply ruin a sensible daily driver.