This just started happening. At a certain height, the bed sticks or shifts and my prints top. Happened two times in a row printing same object, same height. I have no idea.

Do you have any more pics..??

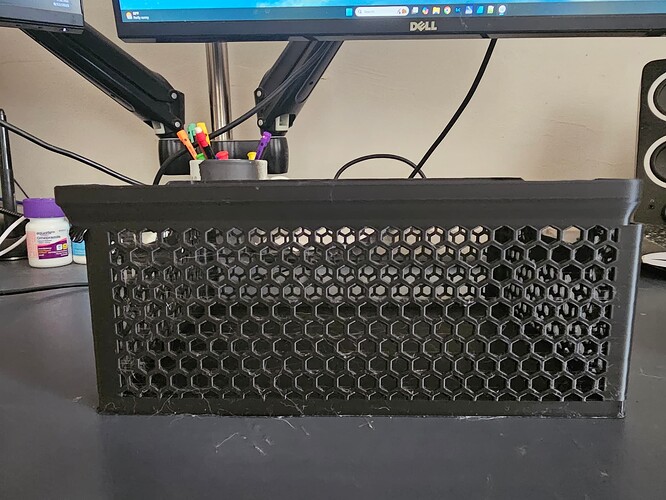

From that pic, it doesn’t really look like a shift…it looks more like the filament didn’t adhere to the layer above the handle.

If you like a your pic where I put the red line, the top of the hexs are complete, they have not shifted. If you have a pic of the other side or a complete view, it would be easier to see.

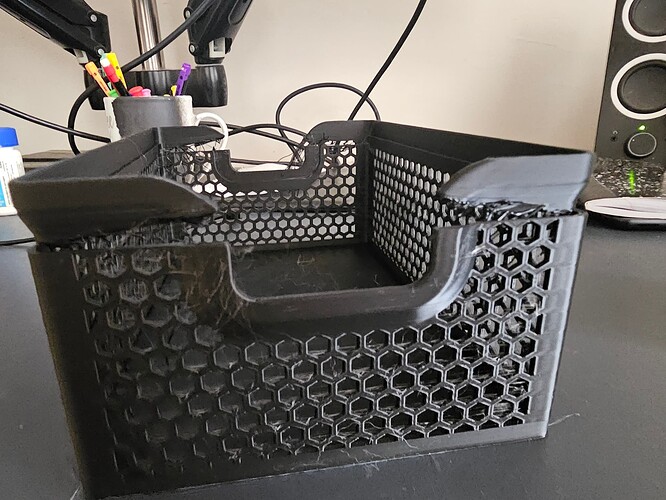

here are a few. yes it seems the ‘sift’ happened above the hex part. It seems to be a one time thing, at that level. Two prints of same thing in a row.

apparently i can only put one pic in a post as a new user. so will try a few posts.

Yep, that’s a shift.

One print work, one print failed…might just be one of those things.

no, unfutnately both prints of same item failed in same spot.

I looked around at others that had that problem and what potential solutions were, set z hop to z, set the infill to a different type (not that there is much if any on this), looked at my belt, it may have been too loose, so tightened that up, and dropped my acclerations down to 2000 from what they were, now trying again, will see in morning I guess. Thanks.

Check your Y axis belt tension. Check anything that could allow your nozzle to drop a fraction of a mm when crossing an opening:

- Rollers on the X rail

- Hot end mounting screws (a SV07+ user just found his hotend was floating free)

- Nozzle is tight (check it at print temperature)

Then turn on “avoid crossing walls” and “Z hop” in your slicer.

And finally, an enclosure (even a cardboard box) will reduce the amount if warpage in the lower part of your print. Another “trick” that sometimes helps is raise your bed temperature somewhere around Z=25.

OK, I misread this part.

You didn’t mention print orientation, but most shifts are on the Y..

I would turn the model along the X and see if it works.

Since it also happened in the same spot on both prints makes me think it’s something with the model itself. Changing the orientation might get around this or it might not.

It’s possible you will really have to slow this model down to finish a print, like maybe 60-80mm/s.

I will do that after work and run again. The one with decreased acceleration and increased belt tension i ran overnight was worse. Lol

Yes try turning it. I’d not go 90° but 75 or 80 so no wall is aligned with the X or Y axis.

I would reslice at 100% infill. The amount of plastic you are saving complicates the toolpath more than it’s worth. Use a “Height range modifier” if you want to not have the “floor” at 100% infill.

Also set “seam position” to nearest. The aligned setting could cause the long fast moves that result in the shift.

Don’t be discouraged, Large flat surfaces in the XZ or YZ planes are one of the hardest things to print. The shrinkage of each individual line of plastic makes them warp a tiny bit and they either pull off the build plate or push a corner up and hook the nozzle. Carbon or glass fiber filled filaments are a HUGE help as the fibers counteract the shrinkage.

Ok, i set 100% infill, and turned it 45 degrees. I have printed several before and they were fine. Yeah I know about that large flat surfaces, i found with this one (and other stuff like it) actually printing the skirt helped keep it stuck down, without the skirt one corner always poked up a bit.

Gonna run in just a bit so will see how it is in the morning. Also read a little more about belt tensioning, i had tightened it, which was when the shift was worse, so I went back down, maybe it had become too tight somehow. Thanks again.

Hello,

I printed something similar, but smaller.

My problem was with the honeycomb pattern.

To fix it, I simply reduced the speed considerably.

I don’t know if this will help you.

I have heard that before. Thing is I have printed maybe a dozen of these before with no issues. Is just suddenly at a certain height doing this. I need to make a smaller model that goes that high to test with because testing with this model wastes a lot of pla. Lol

Well i had created a few tests in fusion, had same failures while using less filiment. then did a full clean, worked for 2, then i started hearing a clicking from the x access. i turn off machine an dpushed it back and forth and feel where it hits harder to move spots and clicks, seems to be coming from the front tensioner sprocket. trying to find source for part, emailed sovol as well.

Just in case.

Did you check if there is no more foam block under the printer?

It’s a classic problem on the SV06ACE.

Yes I saw that issue before mine ever came. So no foam under there.