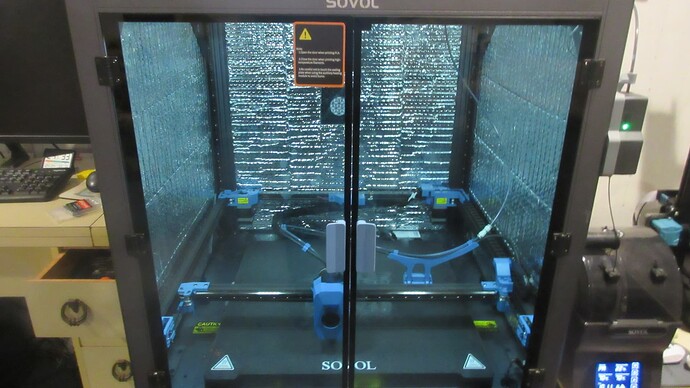

The OEM Sovol enclosure is a nice piece of kit for what it is – shortcomings include that it needs to be taller to accommodate the maximum height, but that can be addressed later. The other shortcoming is heat loss.

The problem is those large metal panels radiate heat like crazy. I want to print ABS with a recommended chamber temperature of 60°C but without a chamber heater the chamber wouldn’t rise above 40°C and turned the printer into a giant radiant space heater. My printer is right beside the computer and I could feel the heat radiating off sitting at the desk!

There is some space between the panels and moving parts, So I added a layer of reflective foil pipe wrap insulation. The product I used was by EcoShades Inc., but I’m sure there are other brands out there. This specific product is 3/16” (5mm) thick with an R-4.3 insulation rating and I bought the 6” x 25’ roll.

The width is perfect – 4 strips wide = one panel. Unfortunately the roll was 26” short and I had to buy a second. One could probably get away with cutting the strips 2” shorter, leaving the bottom 2” of each panel uninsulated since heat rises.

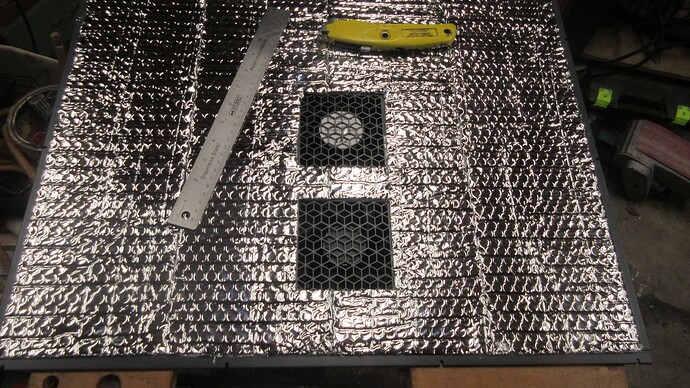

First I masked off the edges, as I was leaving the folded panel edges so as not to interfere with remounting. I also masked off the fans in the rear panel:

I sprayed the panel with 3m 77 spray adhesive. Elmers and Gorilla make similar products that would likely work just as well. NOTE: this stuff is extremely sticky. Be very careful positioning the insulation before making contact as repositioning will likely just destroy the insulation.

The fan mounts made a good guide for the location of the fan cut-outs and the material is easily trimmed with a utility knife and straight edge.

Four strips 6” wide was a perfect fit between the folded edges for the side panels. The top metal panel required 2 and a half strips. I covered the Bowden tube cut-out and just made a slit with the knife in the middle for that to minimize air escape.

As an added bonus, the reflective surface helps with the interior lighting, which was adequate with the tinted doors open but somewhat dim with them closed. They make black filament almost invisible against the black build plate. Now even my old eyes can see something is there.

The difference is amazing. Prior to insulating, the doors were cooler than the sides, now the glass is distinctly warmer. Printing ABS with a build plate temperature of 100°C and all fans off, the chamber temp reaches 52°C near the bottom and 58° at the top. Seems to be close enough for ABS.

It does take 30 minutes or so to reach those temps so a heater would still be helpful to speed the process along, but the insulation will still go a long way to saving energy and keeping the room temperature comfortable. I don’t feel like I’m sitting in front of a fireplace any more.

The thermal camera image clearly shows the benefits: