After first time setup and initial calibration, this first layer print has cumulative precision error further it goes in printing. I saw this error before but I forgot what cause it. Could anyone help?

Hello @sovol3d

Could you help him?

I’m not sure what you mean. To me the X and Y precision shown in the photo seem fine.

The entire thing seems under extruded, minor for the top left, some worse bottom right.

What filament are you using. Even a tiny variation in filament diameter could cause a print like that.

Have you done a “flow rate calibration” for this roll of filament?

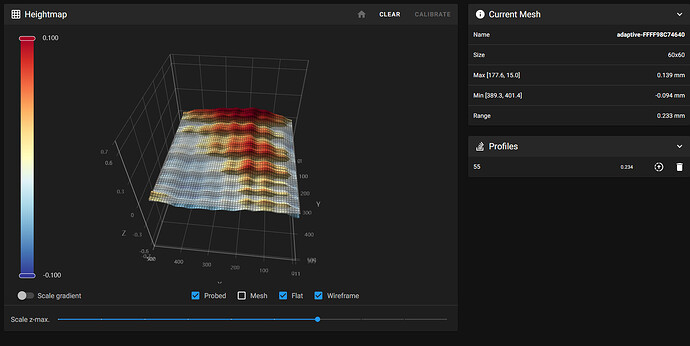

Your mesh could also be “tipped” a tiny bit.

Try switching the solid infill to concentric and run another test print.

I doubt it, I’ve just did belt tension adjustment (tutorial below) and frequency was off by 70 Hz, after calibration and mapping I would try print again. I think that was it

I tighten the belts, calibrated K factor and flow rate. Same issue persist but not as intense as before, so could be there something else I could try?

Did you try these? Might help to sort out the issue.

You can enter the mainsail to view the grid diagram of the hot bed and make adjustments. If one side is high and the other side is low, it may be that the gantry is tilted. It is recommended that you can QGL calibration several times.

I don’t think it’s for me.

@KoizumiChineko it’s probably for you.

@mich0111 Yep I think so.

@sovol3d I will address first layer issues after my first big print, but despite first layer issues after calibration Z quality is near perfect. I will update soon.

Your print seems correct to me.

What more do you want?

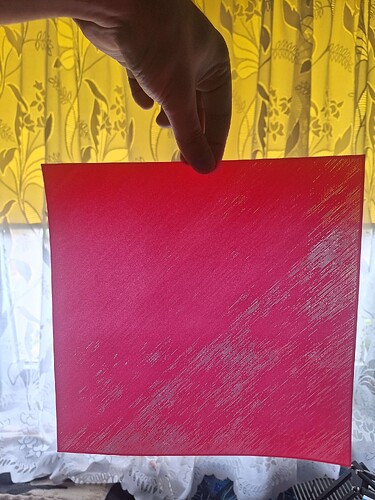

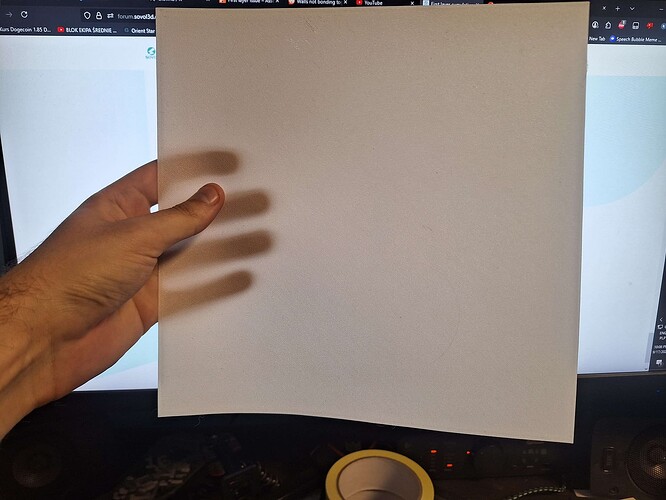

Is this correct looking first layer? That is not sarcasm, I really do not know what is consider good at this printer.

(best tile vs worst tile)

It is a B+, very good but not excellent.

What is your first layer thickness? If you are at 0.2 or thinner then call is an A

Holding parallel planes within 3 or 4 microns across 500mm is not a trivial task.

0.25mm, if it is B+ I leave it as it is. I bought this printer for large prints for smaller ones I have my X1C. Thank you for help

For a dedicated “Big Print” machine I’d go to a .6 nozzle and a .4 initial layer. The bigger nozzle sacrifices very little wall detail. Unless your printing super detail on the top surface you’ll be golden.

@sovol3d I revoked “Solution mark“ because I found root cause. Nozzle has wrong offset (my default 3.5mm is off by -0.09mm) and setting it manually in printer.cfg has no effect even when is set from Klipper screen via manual z offset calibration.

I used filament gCode override, and I think that printer.cfg change has no effect on Z offset is a bug.

Review the Zero forum. I assume Sovol has carried forward most of the macros. On the Zero a Z offset is created by the [z_offset_calibration] Macro (If I recall correctly) with a “hard coded” offset above the point the macro detects nozzle contact.

The process is essentially the same as EddyNG (but apparently rewritten from scratch)