I just got my Zero today. Installed it and made a testprint with the given filament. All good. Unloaded filament and loaded a new full spool with pla+. But it pulled the filament for a second and then stopped.

I unloaded several times and loaded but its stuck in between. Tried to use the needle from botton, nozzle is somehow free, so its stucked somewhere in the middle.

I am now searching for howto solve it. I cannot find any sovol Zero video how to fix it, just 2 pics from the Bad Clog

But i dont know what to do now. The videos from other printers dont help me. I have no idea how to fix it and tried to start disassembling.

The best i found so far is this video https://www.youtube.com/watch?v=zIimdq_HCjE.

But i feel quite disappointed, its a brandnew printer, brandnew filament and its my first filament change and i am now working for hours and hours to fix it.

And its not that i dont have experience with other printer. I fixed a clogged qidi printer and it took me only half hour and all is good. I am able to disassembling it in a few minutes, but the sovol zereo mechanic looks totally differen and i cannot see a way to look into the gear mechanic without completely disassembling everyhting which i really dont want to do the first day of having a Zero.

The Max & Zero are pretty much the same toolhead.

I assume you pulled off the tension lever to check if the was filament stuck in the gears..

Sovol developed the Zero and SV08 Max together. The Zero made it to market first but it seems that Sovol was so focused on getting the SV08 Max to market that they didn’t produce their usual technical support documents and videos for the Zero and just never got around to doing that, making it a bit of a neglected stepchild in the Sovol family.

If you have enough filament protruding from the top of the extruder, I’d recommend pulling the heated filament up to remove it by removing the heat break cooling fan so the nozzle heater can also heat the long heat brake, setting the nozzle temperature to 350 C, removing all tension from the extruder pinch gear at the top of the extruder, and waiting a couple of minutes for the entire hot end to heat and transfer that heat upward into the heat break. Apply steady upward force on the filament and it should stretch once it’s heated, reducing the diameter and pulling up out of the extruder.

Heating the nozzle and heat break should also be a more effective strategy when clearing a clog by pushing down on the filament.

The latest printers are engaged in a marketing war to claim faster print speeds and this is not in the best interest of most customers. I want a reliable printer that’s easy to maintain. The long melt zone and long heat break make printers less reliable and more difficult to maintain. Hot end designs for fast printing PLA don’t print other materials as well and they’re less reliable and more difficult to service. I print a lot of flexible materials and for the last year, foaming TPU-LW, and the long melt zone is very bad for flexible and foaming materials. That’s my only real complaint about the Zero. The extruder is optimized for 600 mm/s print speeds that nobody does in the real world after printing their impressive 8 minute Benchy.

I wish I was there to see your problem in person and offer more useful assistance. The problem can be solved and will yield best to a calm rational informed approach. Take a break if you’re frustrated. It’s good that you’re here looking for information. I’m confident you’ll solve the problem.

Since my Bad Clog in the thread you referenced earlier, I’ve done a lot of printing on the Zero with very little difficulty. It’s been a precise and reliable little workhorse once I understood how it worked. It’s currently my favorite printer.

Thanks for helping. By the time i now fixed it. It was a bit overwhelming to sit in front a totally different machine then i was used to. But you are right, after watching the mentioned video about the SV08, the way to solve it was to screw out the screw with the pressure spring from the pressure lever push the lever completly down to the rights side. Then with a torch light its possible to see inside it and there it was, a piece of white filament broken sitting inside the chamber which was possible to pull out with some fiddling. And some more broken brittle filament which i heated up and pushed it down with the long needle.

This is the first time i solved a clogged printerhead this way and without dissambling it. I was really near to do that, but way to tired, so i took a break and went outside to tank some fresh air which is always a good idea when you are stuck with a problem.

So now the Zero is printing again.

Yes i dont want another ultra high speed fast printer for pla. I dont need that. But i wanted to have a small fast printer with fast reaction time to print hot filaments for technical small parts which i dont want to do on a max large printer. And yes, flexible filaments, too. And i see, that the zero is sort of a bad choice with this long heat break. Same here: “I want a reliable printer that’s easy to maintain.”

I might fix that with an alternative printhead by myself in the future, luckily its all open source, which is perfect.

So if Sovol is reading this: please focus on your customers and dont fight a war who is the fastest! Thank you! And please make some maintenance videos without showing the obvious. And one protipp: don’t add stupid music to videos. leave the music out; it’s annoying.

If the INDX system from Bondtech is all it’s promised to be, I may be upgrading my SV08 to an 8 feeder INDX and my Zero to 2-4 INDX feeders. I do love the Zero design. For me, smaller is better, not because it’s faster, but because it conveniently sits on the desk next to my computer, it’s a very precise printer for my precision functional parts, and the small enclosure heats quickly making ABS parts as easy as PLA. I was originally planning on a chamber heater for the Zero but it passively heats so well that I don’t need active chamber heating for ABS or ASA. I may get a chamber heater if I need to print nylon, polycarbonate, or PPS.

Same here and thats another reason why i got the Zero. Sovol Printers are pretty good, but not the extruder headset, which is not bad, just its imho one of the weaker parts. And if they bond together with the Indx system, this is perfect solution. And i might buy the sovol max with bondtech indx system. And with the zero i see, its a rocksolid printer.

I designed some simple but heavy duty hanging hooks for my new Milwaukee M12 cordless tools in their contractor bags and the little Zero is printing the first one in Siraya ABS-CF. I may see if it’ll support my weight before hanging my tool bags. I love that the Zero can print these functional parts and it prints ABS-CF as easily as PLA. I also love that the Zero is a very precise printer so the parts look great and their dimensions are accurate. I don’t mind that it’s a fast little printer although speed isn’t in my top ten list of important 3D printer features, but I’m printing these ABS-CF hanging hooks at 100 mm/s with a 0.6 mm nozzle so the part takes only 90 minutes to print.

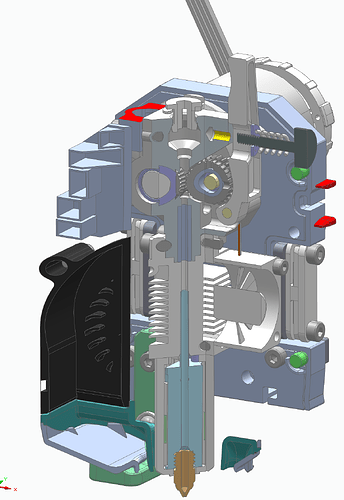

I have not found yet the exact stepfiles from the zero, but from the SV08. And here i made a cut with my CAD System, where i imported the step files from the SV08 to look inside the printerhead which is very similar looking printerhead as the Zero has:

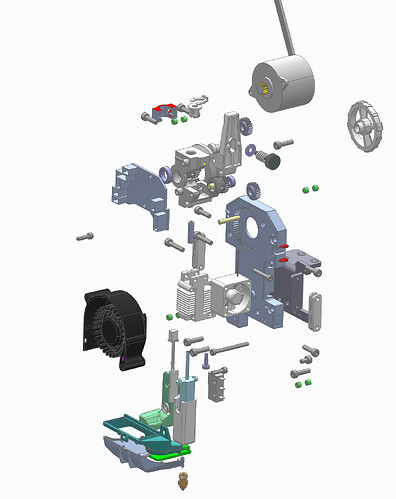

Ok, took me a while. Now i have all step data from the Zero, too. And i can now easily “disassemble” everything inside my CAD system and here we have the cut view from the real zero printhead:

I spent considerable time working with the cad files for the Zero trying to design a water cooled heat sink but it ended up too expensive to be practical.

I’ve also looked at the Max out of curiosity.

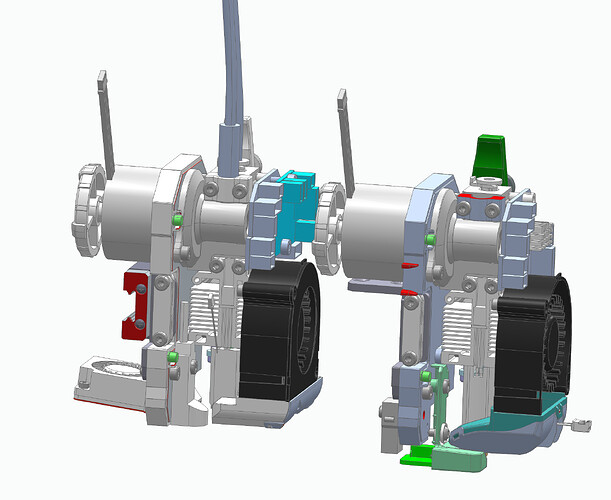

As far as I can tell the ONLY difference is the max has the second part cooling fan mounted on the rear.

And here the solution, inside red circle there have been brittle filament parts extracted to get rid of the clogging. Just screw out and open the green lever and look inside.

yes, you are right, there are only a few parts different, the main head is exactly the same. I can see that in the cad files, which is awsome to have. Left side is the SV08 and right is the Zero.

You’ve shown the SV08 (not Max)

- Shorter heat block

- Proximity switch not eddy.

- USB controller board not CAN

- Thermistor not PT1000

The max is Zero + rear fan

I’m not 100% sure, but I think the nozzle thread size is different.