I first posted to this thread last September (2025). I figured I’d do an update on what’s been happening to my SV08

Modifications

1. Removed the metal bottom shield and replaced the Mainboard cooling fan.

2. Printed and installed mainboard cover and main power cover.

3. MircroSwiss hotend with hardened nozzles .4. and .6

4. R3Men Graphite bed after many iterations of DIY fixes to the stock bed.

5. Installed a spacer to keep the extruder pin from backing out.

6. Lighter toolhead cover with more ventilation and better airflow.

7. Cryo Grip Pro Glacier build plate (2). Also added another Sovol Build plate for a total of four build plates.

8. Mainline Klipper w/32GB EMMC

9. Acrylic enclosure held on with a frame that’s attached to the printer that has magnets int it, more magnets on the acrylic side. Not very airtight but it works for now.

10. Taller feet and vibration pads

11. Double tall tophat with 2 carbon and Hepa filters

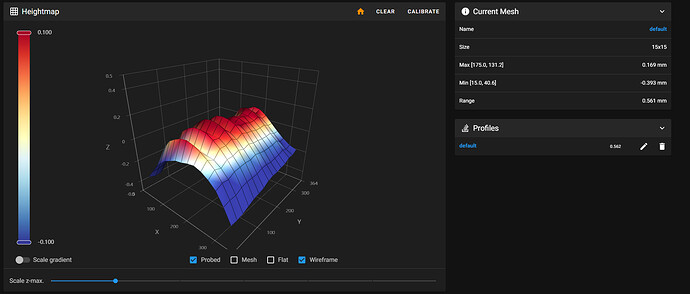

12. Inductive probe to M12 probe to BTT Eddy w/NG software to Beacon Probe. Should have gone to Beacon instead of M12 would have saved myself some money and aggravation.

13. Main platform to gantry cable chain. From gantry to toolhead no chain.

14. Modified the spool holder so spool is parallel to the side of the printer.

Repairs

1. Toolhead cables – 3 of them, Sovol warranty took care of this

2. Toolhead board as a result of one of the cables shorting. Sovol warranty.

3. Mainboard – I fried the onboard USB somehow completely my fault. I bought the silent mainboard

4. A/B belts replaced because they were too short and could not be adjusted evenly or correctly. Sovol warranty.

Maybe in the Future

1. INDX if and when we have a design and implementation for the SV08

2. Make a new acrylic enclosure to make it more airtight.

Overall the printer is printing really well. With the work that has been done to this printer and it’s software/config files, I’m finally confident in it’s ability to do a print without my constant baby sitting.

But, and this is a big one. I probably have at least as much $$$ in the repairs and mods as it cost me to purchase in the first place not counting the aggravation and time to implement all this. It’s a good thing I look at this as a learning and tinkering experience/experiment.